In general, the notion of product must be conceived by integrating all the elements constituting it and in particular the content/container interaction. Among all cosmetic products, if there is one for which this notion is unavoidable, it is the so-called automatic mascara. The major evolution of this product category is strongly associated with that of its application system. Everyone who has worked on this segment knows how important it is. The formula often has a secondary aspect and, very often, the main work of the formulator consists in adjusting his form to the type of applicator chosen, and not the opposite.

In this first contribution on this theme, we will focus on describing the basic system that governs all applicators. In a following one, we will make, with the help of an expert, a detailed review of the various systems, including the craziest that have existed. Other articles on specific systems may complete the picture, but an exhaustive review of all types of applicators is practically impossible. Finally, it should be noted that the"intellectual property" part plays an essential role in this category. This point will be quickly addressed, but remains a major constraint given the somewhat frenetic activity reigning in this field !

Jean Claude Le Joliff

The device

Improperly called automatic, because they do nothing by themselves, automatic mascaras consist of four essential parts that will determine their functionality : - the applicator, - the stem, - the wringer, - the container.

These different elements play a specific role in the performance of the product and must be taken into account specifically, separately or simultaneously depending on the case.

The first element is the applicator itself. If one of the very first products, Rubinstein's Matic Mascara, used a threaded rod as an applicator, the choice quickly turned to brushes, as on the first Maybelline mascaras.

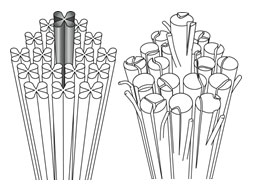

Of different shapes and geometries, they are made of fairly rigid synthetic fibres. Initially made from solid fibers, in particular Tynex™, close to Nylon previously used for making toothbrushes. Profiled fibres have been gradually used to improve the deposit and transfer of the product. These types of applicators have long dominated the category and continue to be at the heart of the offer.

We then saw the appearance of applicators made from silicone elastomers, called"elastomer applicators" or"pin brushes", which are characterized by a very high flexibility, the absence of fibers, replaced rather by kinds of bristles or pins, allowing a different application and feeling on the lash.

The third generation of remarkable applicators is made of injected plastic, known as"injected brushes". The applicator comes in the form of a profiled plastic part allowing the application of the product.

Regularly, we see the return of the applicator combs, made by injection, and which allow to obtain a different make-up gesture, more natural and less loaded than the brush or injected plastic applicators.

Specific shape applicators have emerged with varying degrees of success.

Or the"double mascaras" offering two types of products simultaneously.

For some time now, the trend has been towards a return to fibres, with manufacturers making available filaments of various shapes, the inside of which may be hollow and the outside in relief.

For some time now, the trend has been towards a return to fibres, with manufacturers making available filaments of various shapes, the inside of which may be hollow and the outside in relief.

The second element of the device is the rod that supports the brush. It is usually made of plastic, more rarely of another material.

The third element is inseparable from the stem, is the wringer of the bottle. Indeed, the make-up result depends for a very important part on the quantity of mascara present on the brush. However, if the spin is too effective, it remains little produced on the brush, so little is transferred to the lash. So it's not totally paradoxical that he doesn't wring at all!

The nature of the materials is variable and does not constitute a major technical lock.

The last element of this device is composed by the bottle. This one is of variable shape and capacity. The capacity is generally less than 10 ml, but it is not uncommon to find products called"jumbo" whose capacity may be more important.

The shape may interfere with the perceived quality of the product given the texture of the content. Indeed, the formulas are generally quite thixotropic, and during use, the user proceeds to an important"spraying" of the product before application using the brush. This can make the formula more or less fluid depending on the intensity of the movement. So the same formula, in different bottles, can have a different rendering.

The materials used in these packaging elements vary greatly. Initially metal (Mascara Matic HR), perhaps the most suitable material, other materials have since been or are being used : POE/PVC/PPG/Polycarbonate/Metal/PET, etc.

The technical locks on this station are the sealing at the neck and the porosity of the material. These two aspects can strongly affect the characteristics of the product by leading to accelerated drying, particularly on water-based formulas.

What is important in the design of a mascara, and which makes that it will be effective, is to have a good adaptation between the brush or the applicator and the formula. It is the combination of formula and Essoreur-Tige that makes the success of mascara. In no case does one of these parameters alone make the difference. Hence the importance, when developing the product, to work according to the brush or type of applicator and vice versa.

Patents

This aspect constitutes a particular asperity for this family of products. Indeed, the patent department is accompanied by intense activity on the part of operators, brands or upstream developers (pack suppliers).

Jean-Louis Mathiez of Cinqpats, one of the best experts on these issues, reports What happens in the mascara niche may seem crazy, crazy, crazy…" . He goes on: " Given the demand from the industry for this product , I had to do a real ant's job to perfect the patent history. And if we look at all the levels of patents that go into the design of a mascara, I have counted no fewer than 900. Funny anecdote, the first rotating brush goes back to 1942…, and even the Moulinex group is at the origin of a patent for a rotating spring mascara registered in 1976. But it is especially from the years 2000, and more particularly 2004, that deposits appear for electric mascaras. Even leading electronics companies like Samsung or Matsushita have patented vibrating, heating or rotating systems". .

This clearly shows how active this segment is and how the intellectual property battle is extremely dense. Patents cover all aspects of the product, be it formulation, packaging elements, manufacturing techniques, composition, etc. A very particular attention on the part of the developer must therefore be paid on these various questions. This exercise is particularly difficult because of the multiplicity of patents, their wording that does not systematically refer to the subject or object being sought, and especially the interpretation that can be made of them.

Performance evaluation

Given the importance of this parameter, the evaluation of the performance of the formula/applicator system is crucial.

There are several ways to approach this issue. - The first, the simplest, consists in testing the product under development in a real-life situation. The observer is often judge and jury, and therefore the assessment is very subjective. One of the best ways to avoid this is to use expert panels to classify products, compare them and evaluate them. - Metrological evaluation has been attempted by some in trying to develop standard application systems allowing the evaluation of different parameters, such as the quantity of product applied, the thickness formed, the radius of curvature of the eyelash after drying, etc. None of these systems make reference.

Quantitative claims such as increased lash thickness, curvature, lash growth and others should be specifically assessed. In this case, supervised use tests are generally used, coupled with measurements using digital image analysis. These tests are often cumbersome to conduct and generally do not take place in development procedures.

|

This contribution is the result of a four-handed collaboration, a little like in the development of this type of product: those of the formulator on the one hand and the packaging engineer on the other. The point of view of the formulator was approached by Jean Claude Le Joliff, having worked a lot on this family of products in his various professional experiences: Bourjois, Chanel, but also Intercos or Mascara Plus. On the packaging side, Jean-Louis Mathiez brought all his expertise, also acquired through numerous projects for Bourjois, the Coty group (Rimmel, Margaret Astor, etc.) and others. He also holds numerous application device patents for this family of products. |