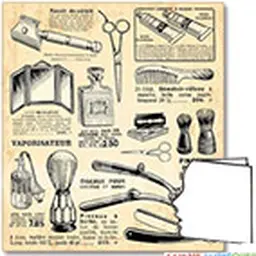

In the make-up world, among all products, if there is one for which the applicator is essential, it is mascara. Indeed, impossible to apply the product without this utensil. Whether it comes in the form of a stick as long ago (the traditional Khôl), a small brush to moisten or apply the product in the early nineteenth century (Eugène Rimmel) or in the form of these famous"automatic" applicators that will invade the market from the 1960s, mascara applicators do not stop making the news.

If we want to understand the whole technological offer on this point, we must therefore make an inventory, which obviously cannot be exhaustive, of the different types of applicators. The whole of this work was carried out in collaboration between two men of the art, a formulator and a packaging engineer. More than ever, collaboration between these two fields is necessary for the development of high-performance products. Jean-Louis Mathiez is one of the very best experts on this question. Our discussions around these issues have made this contribution possible. We will take this opportunity to evoke some original attempts such as we can discover them in the forest of patents surrounding this family of products

A few words from our glorious veterans

Among the very first mascara applicators, the one patented by Helena Rubinstein in 1958 is quite remarkable. Manufactured by Schmidt und Niedermeier, a metalworking company, it is considered quite probably one of the very first devices of its kind. This product is very simple and still offers very interesting performances to date. Made of a metal tube, the applicator comes in the form of a metal rod permanently dipped in the product, at the end of which a simple thread allows the application of the product.

The all-metal construction of the unit will avoid many compatibility problems, but will also resolve in a very satisfactory way the two central issues of this type of packaging: the loss of tightness and porosity of synthetic materials. Indeed, these questions often lead to products evolving in such a way that they dry or thicken strongly, opposing a good application of the product.

In 1959, Maybelline Magic Mascara launched the first twisted filament brush. Then in 1964, the American brand launched the first mascara tube for the general public: Ultra Lash mascara.

After being dominated for a long time by brushes of all shapes and natures, the world of mascara applicators will evolve very regularly. To date, it has been an almost permanent field of innovation, as brushes have been supplemented by various types of devices. Finally, this is an area in which patents play an absolutely essential role. Mascara is a field of intense creativity with more than 2,500 patents worldwide on packaging, formulas and new application methods.

The different types of applicators

The brushes

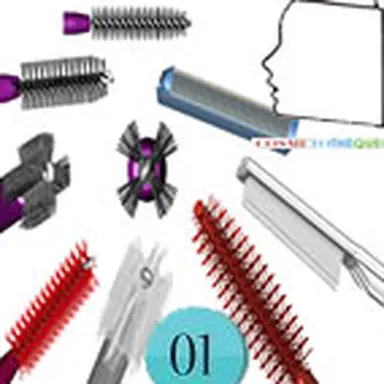

There are several types of brushes that can be classified into three broad categories: - twisted brushes - injected brushes - combs

Twisted brushes are the oldest. They come from a technology applied more specifically in the world of brushing. This is the case with Ponzini. An original story that of this company from the Milan region which started one day in 1862 with the manufacture of carriages and"equipment" for horses. And in this"equipment", there are obviously brushes. It is this activity which will be definitively amplified by the descendants of the Ponzini creator in the middle of the 20th century: hair brushes, toothbrushes, first small brushes to apply the first mascaras of the market.

These brushes thus have as origin the manufacturers of brushes in general, toothbrushes in particular. Initially made with natural hair, wild boar hair among others, including the flower of the hair to obtain good flexibility, they will quickly be made from synthetic fibers more suitable for these applications. Nylon and polyesters will be the most widely used polymers. This is the case of a fibre developed by Pont de Nemours over 75 years ago, Tynex®, derived from nylon. This fibre has interesting properties both of rigidity and compatibility with the products. It is a filament extruded-drawn from a Nylon 6.12 following a process developed for textile fibers. The section was simply cylindrical at the beginning, but it could take complex shapes as the process evolved. Another manufacturer will offer polymers suitable for these uses, Hahl Pedex as Nylons 6, 6.6, 6.10, 6.12, Polyester PBT and LDPE. Other specialties of the same type will be used by companies such as L'Oréal, developed in exclusive partnership with major chemists (Elf, Total) and with similar materials.

The principle consists in fixing twisted fibres on a metal rod. The twists obtained are then cut according to the use that one wants to make of them. In the prototyping phases, it is reported that these brushes are cut with hair clippers before being subjected to a very complex industrialization.

The first brushes will be relatively simple, then little by little they will become complicated on practically all levels: shape, length, nature of fibres, turns, pitch of turns, texture, coating, grinding or in finishing operations, cutting in particular. One can summarize by saying that the main parameters on which one can play to develop a brush are: the diameter of the rod and the wringer, the filaments of the brush, its design and its stiffness. Developers don't deprive themselves of it.

These parameters change regularly. This is how the manufacturer of Tynex™ proposes new forms of fibres, textures, which allow them to adapt well to the application of new formulas on lashes. We can cite the success of the"Tynex® Hollow" fibre, which is very"trendy", but also"Sea Horse","Super Soft Splittable","Quadrilobal", etc. They are filaments of various shapes, the inside of which may be hollow, the outside of which may be raised, etc.. Then, it is all the know-how of the brush manufacturer which will have to express itself on the level of the way to cut the fibres to give them such or such original characteristic in term of retention of the formula and restitution of this one at the time of the application.

Injected brushes, also called"hard applicators"

The particularity of these applicators is that they no longer have fibres associated with the applicator, but moulded profiles allowing the application. These products are made by micro injection. They make it possible to obtain different profiles. Many patents exist on this technology. The most remarkable products are or have been developed by the L'Oréal brands (Hypnose, Fatale) or the Coty group (Calligraphy, Rimmel).

There are several types of injected brushes. - Single-material injections. In this case, the most used materials are polypropylene, low density polyethylene or thermoplastics such as Hytrel™ de Dupont de Nemours. - Bi-material injections: see the elastomer chapter below.

The combs

The combs are to be classified in the part of the injected brushes. This type of indicator has been used for over 30 years. There are many different shapes of comb. They are made by plastic injection. One of the recent evolutions consisted in associating in the same applicator a comb part and a brush part to try to modulate the application.

Elastomers

They are in fact injected brushes resulting from a technology called bi injection, or bi-material injection. The applicator consists of a rigid core and soft plastic bristles. The essential condition in this case is compatibility between the materials. This technology concerns almost essentially the applicator. The origin of the technology is to be found in a brush manufacturer, Coronet, following the purchase of the patent by Geka. The applicators are made with a particular moulding technique, Moldtrusion®. A small tube is filled with material under very high pressure and then injected into a system equipped with micro-holes, each corresponding to a hair. This is a very fine technological achievement. The result is very soft pimples that are easy to apply, but also have a gain in sensory properties, the pimples on these brushes being much softer than polyamide fibres.

The first products made and marketed with applicators of this type were signed by Nivea (Revolution in 2004) or Chanel (Chanel Inimitable).

To date in 2016, applicators continue to become more sophisticated on a regular basis. A recent development of the Albéa group, Doe Eyes Brush is a double-sided plastic brush specially designed to recreate the professional make-up artist's gesture. Its round side receives the formula and deposits it on the lashes, then the"comb" side allows to apply it carefully to obtain the best shaping and lengthening effect.

Two recent developments based on technology such as that used by this applicator, proposed by the L'Oréal brand, can also be mentioned. It is an injected elastomer brush (TPE). Its particularity is to have a very fine"arch" that forms a flexible comb. This brush was created by SIMP in Draveil. The model is reserved exclusively for L'Oréal, but it is possible to use the same technology by changing the shape. One example is Essence Maximum Volume mascara.

Wringers and rods

These two elements also play a significant role in product performance.

This is how the diameter of the brush holder rod plays a role in this assembly. It is generally considered that a thin rod leads to elongating mascaras, when a thick rod is the base of a volumizing mascara.

As for the wringers, they must be developed specifically taking into account a particular matrix of contradiction: how to have enough product on the brush to allow a fast load of the lashes, without the stem being soiled with mascara. In the case of particular applicators, such as asymmetric comb applicators, for example, they must take into account the particular geometry. In many cases these are very innovative devices. A good example of this type of realization: Grandiose de Lancôme.

- To follow, with The Magic World of Mascara Applicators - Part 2 .

| Contribution by Jean-Claude Le Joliff and Jean-Louis Mathiez This contribution is the result of a four-handed collaboration, a little like in the development of this type of product: those of the formulator on the one hand and the packaging engineer on the other. The point of view of the formulator was approached by Jean-Claude Le Joliff, having worked a lot on this family of products in his various professional experiences: Bourjois, Chanel, but also Intercos or Mascara Plus. On the packaging side, Jean-Louis Mathiez brought all his expertise, also acquired through numerous projects for Bourjois, the Coty group (Rimmel, Margaret Astor, etc.) and others. He also holds numerous application device patents for this family of products. |