The application of nail polish is a fundamental operation for the final quality of make-up. The essential accessory of this step is the brush. It has gone through time despite many attempts to change it, but overall it remains the same. Jean-Louis Mathiez, expert in cosmetic packaging, tells us a little more.

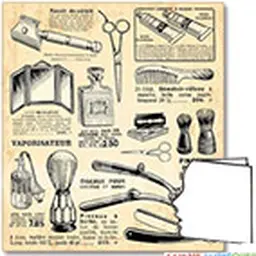

A fashion product par excellence, nail polish was born in the United States in the 1930s with the Revlon brand. Two brothers, the Revsonsons and a chemist friend, Charles Lachman, Revlon's L, invented opaque and pigmented nail polish. This is the beginning of an adventure that will lead them to build an empire. Until then, the varnish was colourless or slightly tinted, and of poor quality. The introduction of coloured pigments will bring this cheerful touch that will make all the difference.

Later, in the 1950s, Cutex would claim to be"The inventor of plastic varnish", as shown by an advertising poster of the time. This brand still exists in the United States. In England and Spain, it is distributed by Coty.

Originally reserved for an elite group, the Hollywood stars, and available in only a few shades (pink and red), the varnish was presented in a small glass bottle accompanied by an independent brush, just like an inkwell.How far we've come since…

It owes its renewal today thanks to the madness of Nail Art which came from Asia in the years 2000 and which breathes an unbridled and limitless creativity. Colours, graphics, cracked, metallic effects, mirrors…, professional techniques, never before has a make-up product undergone such a revolution.

But one element remains essential: the applicator,

from the brush to the pen, passing by the printer for the nails, the history of this indispensable accessory incites curiosity.

The brush, the timeless object of all lusts

Just as the lipstick is a symbol, the nail polish brush is ultimately the optimal applicator.

The evolution of the brush will be mainly at the fiber level. The ideal would be to obtain the performances of an artist's brush in natural fibres (wild boar silk, marten or badger hair), but the cost and the rapid deterioration due to the impregnation of the substances constituting the varnish prevent their use. Let's not forget that the brush spends more time in the varnish than outside!

The fibres are therefore mainly made of polyamide (nylon), sometimes polyester. The most commonly used material is Tynex®, a fibre proposed by Dupont de Nemours, the great American chemist. This fibre is also used to make a whole series of brushes and applicators, such as toothbrushes for example. There are several types of fibres and the choice is decisive. It is mainly on this criterion that the qualities are articulated.

Many attempts to substitute the fibres with foam tips or very soft spatulas (pallets in the jargon) have not been as successful. The brush and its nylon fibres seem uncontrollable!

In contact with the varnish, these fibres react and evolve towards optimal flexibility by impregnation. In addition to the nature of the fibres, their diameter, number and arrangement play an essential role, as well as the tapering (sharpening of the end of the fibre).

400 to 1,000 fibres can be used in a brush.

The manufacture of the brushes is highly technical and is covered by numerous patents, including more than a hundred for the L'Oréal group alone. They concern the fibre mixtures, the shape of their section (star-shaped, rectangle-shaped, twisted), the treatment carried out to better retain the varnish, the presence of a reservoir… where the double"stacking" brush.

Attempts to Break

In recent decades, we can say that nail polish has changed little in terms of packaging. The bottle is still made of glass (recyclable) even if good performances have been obtained with a transparent and solvent resistant plastic material (PA Grivory from EMS, Switzerland).

It would seem that glass remains the absolute symbol for optimal preservation of the qualities of varnish (this is the perception that users have).

As for the brush, it has been optimized to the maximum, but always on the same model.

But the Japanese of Mitsubishi (manufacturer of pens), with their experience in calligraphy, developed, more than 20 years ago, a pen for nails. The difficulty lies in the fact that the formula of varnish must dry as quickly as possible once placed on the nails (requirement of the consumer), but on the contrary, it should not dry too quickly for its conservation… A real headache for the designers of the nail pen! The solution would be to re-dilute the formula, but how? The trials with varnish pens have so far proved unconvincing. Regularly, they reappear with the same constraints.

Anyway, maybe a revolution is underway with the nail printer.

The 3D printing revolution

The arrival of the"nail bar" and the"nail art" in Europe made things happen. Already very popular across the Atlantic, with professional brands like Sally Hansen, nail make-up is undergoing a upheaval.

Very recently, several brands have launched high-tech kits in mass distribution with a UV lamp and multi-component formulas, for ultra fast drying and above all exceptional varnish resistance. These products are commonly called"gel varnishes" or semi-permanent. The pioneering brands are Essence and Catrice in Germany (Cosnova Group) and Essie in France (L'Oréal Group).

The next step is undoubtedly the nail printer. Simply apply a base and the printer will drop a preselected pattern. And it's already possible in New York!

Jean Louis Mathiez, Director of Cinqpats

Expert in packaging, Jean Louis Mathiez has held various positions within major international groups. Revlon in the 80s, as head of the packaging validation laboratory, Bourjois and Chanel for 7 years in the Quality and Packaging Research division, then he joined L'Oréal in 1997 where he was in charge of the operational development of make-up packaging for the Maybelline and L'Oréal Paris brands.The adventure will continue at Coty (formerly Benckiser Group), where strategic innovation will play a dominant role.

From this experience Cinqpats was born. Initially exclusively for Coty, it will operate autonomously from 2007, and

today Cinqpats works both for the ultra-luxury segments and for mass distribution, particularly in Germany.

Its most significant product

The pen mascara (Extreme Volume by Rimmel and Calligraphy by Astor) in 2000,

the first mascara with plastic comb applicator combined with pen-shaped packaging. Very big success with several million units produced/month.

Its biggest flop

All electronic application devices such as vibrating, rotating or even heating mascaras, which have had a mixed success in selective and which have totally failed in mass-market.

Michelle Vincent