Christine Lauth and Olivier Thierry are pleased with the management of the Pastel project within the Bourjois/Chanel organisation. It consisted of the recultivation of pastel in the Toulouse region and the preparation of an oil for cosmetic use. Nowadays, this project might seem pretty obvious. In the late'80s, it was much less so. The team in charge had to carry out a great deal of work to cover all areas, from production to formulation, including the differentToday, this approach would undoubtedly be called CSR. Bravo for this work and thanks to them for this story - Jean Claude Le Joliff

It was in May 1988 that the first meeting took place between Professors Gaset and Delmas, from the Laboratoire des Agroresources of the École Nationale Supérieure de Chimie de Toulouse, and Bourjois, represented by Christine Lauth and Jean Claude Le Joliff. This contact followed an article published on pastel in La Dépêche du Midi entitled"La deuxième chance du pastel", cut by Christine Lauth's father who had sent it to her daughter.

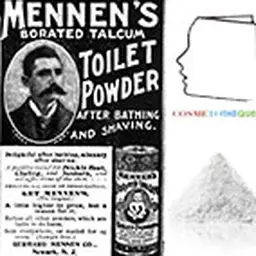

The relationship between pastel and Bourjois was obvious since the small round boxes bearing the same name made, among other things, the reputation of the brand.

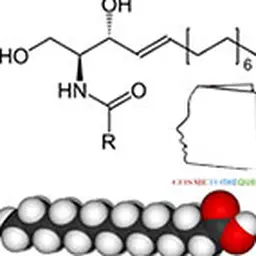

The plant had made the fortune of the land of Cocagne for the supply of the"pastel blue", obtained from the leaves. Within the framework of the valorization of the plant, the recultivation starting from seeds found at INRA had made interest in the seed. The composition of the oil determined by the Agroressources laboratory had revealed a richness in polyunsaturated fatty acids that could be of interest in the cosmetic field.

In December 1988, a meeting was organized with all the actors involved in a pastel exploitation project, namely the seed-producing cooperative (CAL), the oil manufacturer (AGRO CINQ and its subsidiary EPM), Professors Gaset and Delmas who had worked on the composition of the oil and the potential exploitation of its constituents, and Bourjois.

The decision in principle concerning the cosmetic use of pastel oil was taken in mid 1989. At that time, the crop yields of the plant and the reproducibility of the seed composition remained to be confirmed, the process for obtaining the oil to be chosen (extraction by pressing or solvent) and, consequently, the type of preservation and the control criteria for using a vegetable oil of constant and reproducible cosmetic quality were to be determined.

Coopérative agricole du Lauragais

In 1985, the Coopérative Agricole du Lauragais (the"CAL", now the Occitan Cooperative Group), in collaboration with the Agroressources laboratory, began experimenting with pastel cultivation at the Loudes farm in Castelnaudary (a farm we will visit under Mr Mailhol's guidance), to determine the optimum conditions for growing the plant.

Next to the pastel, the CAL, very dynamic, carried out various studies and, among these, cross-pollination trials: two varieties of plants were cultivated in a greenhouse and the bees which were released there did the work of hybridization.

The pastel is sown at the end of summer (September - October) to be harvested in June.

The expected yields in 1989 were in the order of 200 kg of seeds per hectare with a good hope of raising them to 400 kg/ha.

Oil production

A vegetable oil can be obtained by pressing or solvent extraction. For pastel, the first tests were carried out in Toulouse on an oil obtained by solvent extraction with yields of around 25%.

As part of the preliminary decision-making study concerning participation in the project, a first sample of 200 g of crude oil extracted by solvent arrived at Bourjois in May-June 1988. The product was coloured, smelly (hay-luzern) and did not really look like a raw material that could easily be incorporated into a cosmetic product !

After some preliminary studies, it was decided rather quickly to work on a virgin oil, namely obtained by cold mechanical pressing, without solvent, clarified by physical or mechanical means and without any physical or chemical refining treatment nor addition of additives. (Definition of"virgin oil" - Decree 64-1166 of 19/11/1964)

This choice makes it easier to control the organoleptic characteristics of the oil (colour and smell) and its composition. In the 1990s, the name"virgin oil" began to become an important claim.

Analytical Research

With the help of a student engineer from the Ecole Nationale Supérieure de Chimie de Toulouse - Laboratoire des Agroressources, on a six-month internship at Bourjois, it will be possible to determine the conditions for storing the seeds, extracting the oil, storing it and the"identity card" concerning the composition of the oil.

The qualitative and quantitative compositions of unsaturated fatty acid in oils obtained by solvent and pressure are similar. There is a difference in oleic acid from 23% to 13% of the total fatty acid composition.

All the elements of knowledge of the oil (analytical, toxico-tolerance) will make it possible to feed the European legal files as well as the registration of the matter in Japan.

The name INCI will be given under the title: Isatis tinctoria seed oil.

Oil stabilization

The oil, given its richness in unsaturated fatty acids, was easily oxidizable. After numerous accelerated ageing tests by adding conventional antioxidants, and in order to preserve the virgin oil character, it was decided to condition it under inert gas (nitrogen) in 10 kg cans corresponding to whole multiples of the quantities used in industrial manufacturing, thus minimising the potential risks of oxidation linked to processing.

Subsequently, in the cosmetic formulations, the oil concentration and the choice of an appropriate antioxidant system made it possible to stabilize the preparations without any problem.

Industrial" cultivation

The first cultivation under the project was carried out by five farmers on 25 hectares in October 1989 for a first harvest in June 1990. After mowing, drying, separation of seed silica, cleaning and drying, the production will produce 800 kg of oil by pressing, roughly corresponding to the yields calculated during the experimental recultivation.

Seed storage

For safety, half the annual seed production will be stored in two silos at a temperature below 10°C and for a maximum of two years, studies having shown that the seed degraded beyond that.

Project Life

A patent was registered in 1991 on"a mixture of vegetable oils rich in essential fatty acids and its use in cosmetic compositions". This mixture contained pastel oil.

The mixture was introduced in Bourjois make-up ranges and in a Chanel skincare range.

Bourjois continued to benefit from the non-compete obligation until the end of November 1993.

This was the first time that Bourjois was directly involved in obtaining one of its raw materials, from growing the plant to producing the oil, and that the R&D laboratory followed the operation from A to Z. At the time, Pantin's R&D laboratory was looking for a vegetable oil of tropical or exotic origin that was out of the ordinary. It was in the Land of Cocagne that he found her!

| This contribution was made by Christine Lauth and Olivier Thierry. Both worked on the Pastel project within the Bourjois/Chanel company. They were the ones who brought it to a successful conclusion. They're telling us today. After studying pharmacy, Christine Lauth turned to cosmetics. She started at Stendhal before joining the Bourjois/Chanel organisation where she held responsibilities mainly in the R&D of the Skin Care formulation. Olivier Thierry is a chemist by training. After his first experience in the control laboratory of a pharmaceutical company, he continued his professional career in the cosmetics field, first at L'Oréal, then in the Bourjois/Chanel R&D department. Successively in charge of the raw materials control laboratory, then the analysis laboratory and the technical expertise laboratory, he finished his professional activity in 2011. |