Amino acid derivatives constitute a very broad family of ingredients with multiple functionalities. We have already treated some parts like biopeptides or lipoamino acids. Another particularly interesting family is glutamic acid derivatives, better known as"acylglutamates", which are of major interest as the basis for formulating foaming preparations of all kinds. These are remarkable surfactants. Virginie Gerenton, who has taken a lot of care of it in recent years, makes us travel in this universe. Thank you to her. Jean Claude Le Joliff

At the heart of lipoamino acid chemistry, acylglutamates aroused the real interest of European cosmetics in the late 1990s, for applications in rinse-off products. Recognized from a scientific point of view as soft multifunctional surfactants, these surfactants are the best in the world. hyper The active ingredients have many facets and are still very promising for the years to come.

Back to the roots

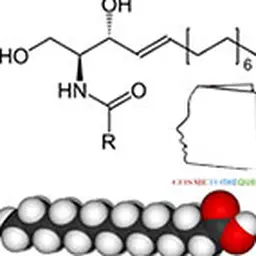

Acylglutamates are composed of one or more C8-chain fatty acids and L- glutamic acid, and are obtained by acylation reaction.

Originally, Japanese researcher Kikunae Ikeda identified the taste umami (tasty) in 1908, as glutamate. He discovered that the kombu seaweed broth contained some, but also vegetables, meat, fish, fermented products. He patented the industrialization of a sodium glutamate seasoning under the name Ajinomoto and in 1908 associated himself with Saburosuke Suzuki, a Japanese industrialist, to produce and market his invention. Since then, sodium glutamate has been used in food as a flavour enhancer.

It was in the 1960s that important research was conducted on acylglutamates as mild anionic surfactants. The first grade of acylglutamate was launched by Ajinomoto in 1972 and used for the first time in a dermatological cleansing bread by Yamanouchi Pharmaceutical Co. in Japan.

In Europe, cosmetics manufacturers became interested in this chemistry in the mid-1990s. Beiersdorf has worked a lot on Sodium cocoyl glutamate, and was one of the first European groups to use it in its products put on the market in the mass distribution network. A new generation of hygiene products was born, more qualitative and respectful of the epidermis structure.

In 1995, the Z&S Group was the first raw material manufacturer in Europe to produce acylglutamates at its Italian plant in Tricerro and continues to innovate in this field.

Industrialization processes: towards a sustainable approach?

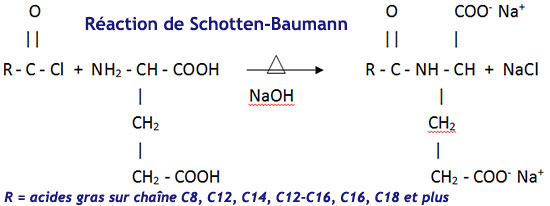

Acylglutamates in neutralized form are obtained by reaction of a fatty acid chloride with glutamic acid, following the Schotten-Baumann reaction as shown below in the case of neutralization with sodium salt:

Sodium salt can be replaced by potassium salt. It is also possible to use organic salts such as TEA.

A solvent is required in the industrialization process and thus gives a reaction by-product, in addition to the residual salt from the Schotten - Baumann reaction. Solvents used may be hexane, acetone, isopropyl alcohol, propylene glycol, propanediol.

Different approaches exist in the chemical industry, following the main Schotten-Baumann reaction: - separation with inorganic acid to remove salt and solvent followed by neutralization: the final product is of high purity but the process used requires several steps with high energy consumption ; - the salt is retained at the end of the process and the solvent is distilled: this is a more sustainable approach than the previous one but requires an additional step to the main reaction ; - salt and solvent are retained at the end of the industrial process: this is the most sustainable one-step approach. The choice of solvent is therefore essential and can, in the case of propanediol, bring additional benefits to acylglutamate, such as hydration or improving the solubility of formulations.

Although the purity of the grade of acylglutamate obtained is essential, manufacturers note a growing demand for cosmetic brands for grades resulting from a sustainable approach.

Another important point in this sustainable approach is the vegetable and renewable origin of the raw materials constituting an acylglutamate. The fatty acid comes from palm nut oil, RSPO ("Roundtable on Sustainable Palm Oil") if possible, or coconut oil. Glutamic acid comes from the fermentation of sugar beet molasses or wheat.

The importance of glutamic acid and fatty acids for skin and hair

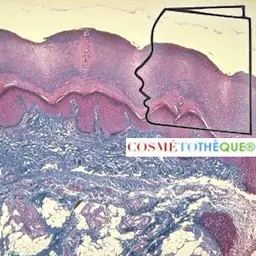

Glutamic acid and fatty acids are physiological components of the skin and hair. Glutamic acid is an important amino acid of the NMF (Natural Moisturizing Factor) of the epidermis and a precursor of PCA, but also of proline and hydroxyproline, two essential amino acids in the synthesis of collagen and elastin. Keratin contains 15% glutamic acid.

Free fatty acids in the stratum corneum represent 25% of the total amount of lipids in the epidermis. They are essential to the skin's barrier function.

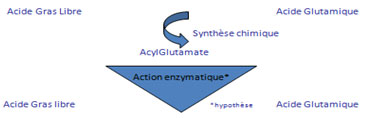

During the keratinization process, the process by which the stratum corneum is obtained, a large amount of enzymes from Odland bodies are exocited into the extracellular environment. These enzymes can cleave different substrates.

If an acylgmutamate is applied to the skin, it is cleaved by these enzymes and the two original components are then obtained: fatty acid and glutamic acid.

This means that there will be no surfactant residues on the skin or hair, a specific and essential property of acylglutamates and acylamino acids in general. By applying these surfactants, the skin and hair are given back its physiological components.

Properties of acylglutamates

Tests performed by the Z&S Group

Non-irritating surfactants

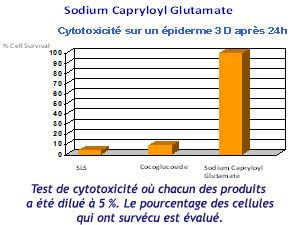

Acylglutamates, regardless of the fatty chain, are non-irritating.

100% of the cells survived in the presence of Sodium capryloyl glutamate. The same is true for longer fat chains.

Non-Defatting Surfactants

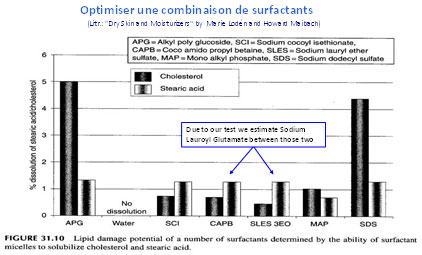

Cholesterol, for example, belongs to the intercellular lipids of the corneal layer which play an essential role in the skin's barrier function. It must not, or only slightly, be dissolved by a surfactant introduced into a cleaning formula.

Sodium lauroyl glutamate, and acylglutamates in general, whatever the fatty chain, are nondelipidants. They remove squalene, an important component of sebum, but not the intercellular cement lipids essential for proper water maintenance of the stratum corneum. This is called the selective cleaning power of acylglutamates.

Active properties linked to the fatty chain - glutamic acid

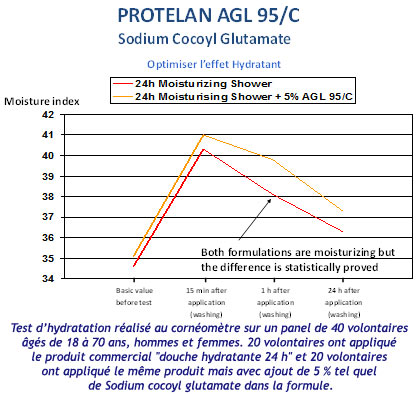

An example with hydration for cocoyl and lauroyl :

Sodium cocoyl glutamate significantly improves the moisturizing effect of rinse-off formulations. It also reduces the adsorption of SLES (Sodium lauryl ether sulfate) on the skin and is a hydrophilic O/W emulsifier with the possibility of a cold process. It can therefore be used in rinsing products and not rinsed. The same applies to the lauroyl chain. These are the two greasiest chains currently used on the cosmetic market.

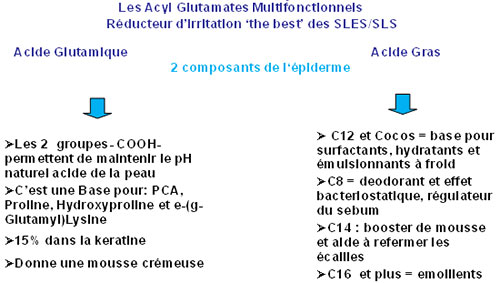

The diagram below summarizes the different active properties of acylglutamates according to the selected fatty chain, added to that of glutamic acid.

The Z&S Group offers a wide range of acylglutamates under the brand name"PROTELAN" with a sustainable and innovative approach.

"Nugget," yes, those tensio- hyper- assets are!

Multifunctional, providing multiple benefits to the skin and hair, they are very modern and perfectly meet the expectations of 21st century consumers while greatly facilitating the life of formulators! They allow to formulate in a reasoned way products to rinse and not rinsed, while respecting the famous"Less is More": less ingredients, more benefits. They fit perfectly into a sustainable and responsible chemistry.

| This contribution was made by Virginie Gerenton. After a DEUG in Structural Sciences of Matter, Virginie obtained a Master's degree in Sciences and Techniques Physico-chemistry of Formulation Cosmetics, Perfumes and Flavors Option at the University of Sciences of Montpellier. She completed her training with a Marketing Valence with a DESS at the IAE in Dijon. More recently, she followed a course as an auditor in Culture and Innovation Management at the CNAM in Paris. After a first stint in a technical position at Uniquema, she took on various responsibilities in marketing and sales functions in the surfactant and surfactant world. For over 10 years she was Sales/Marketing Manager France at Zschimmer-Schwarz France. |