The use of treated pigments, and more generally of coating treated fillers, has become one of the basic technologies in the formulation of make-up products in the cosmetics industry. As always, it all started in the 1970s with some form of stammering, before becoming a constant affecting virtually all products. The goal is not only to improve their performance (feel, texture, sensoriality, strength, stability or even hold), but in many cases now, to significantly improve implementation procedures. These questions are essential in make-up technologies. The feasibility of many products is now directly dependent on these technologies.

Given the multitude of treatments involved, we are practically at versions type 3.0. A point on the origin of these technologies and their characteristics is necessary. We hope that the mysteries of silane, polydimethylsiloxane, alkyl titanate, amino acid and other specialty treatments will no longer have any secrets. This activity having become a Japanese speciality, nobody was better placed than a Japanese expert in these questions to build the best state of the art. Takumi Tanaka, one of the best experts on these issues, helps us understand these approaches, with the help of Serge Grizzo, another recognized expert on these issues. Thanks to them for this contribution.

Jean Claude Le Joliff

The history of surface treatment of pigments and fillers for make-up products

The use of make-up products for the body and face dates back more than 100,000 years. Several natural pigments, generally derived from the soil as mainly coloured earths, were used to protect the body from external aggressions. Appearance was an important factor in social life. Humans sought the appearance of the sun and red coloured earth was the most used. Long after this initial period, other colors, blue, green, and shiny particles were used in the eye area by the upper classes of society. At that time, make-up became essentially decorative. More recently, consumer expectations have evolved towards more features. To meet these requirements, surface treatment technologies have been developed since the 1970s. Nowadays, these techniques play an essential role in modern make-up formulas. This article traces the history and properties of pigments and surface treatment techniques.

The history of surface treatments for cosmetics

In a famous Japanese short story written in the year 2001, Sei-Shonagon wrote:"… When the Empress asked me'How are you?', it was a joy for me. I cried and shed tears of joy. At that moment, my makeup disintegrated. I was ugly and ashamed. His Highness came to me and hid my face with a fan, but she took it away for fun. At that moment, I wanted to hide my face in the sleeve of her kimono, but the white makeup on my face immediately transferred to her pretty kimono. I was full of confusion" . This anecdote confirms that make-up stability has always been a big problem and there has long been a demand to solve it.

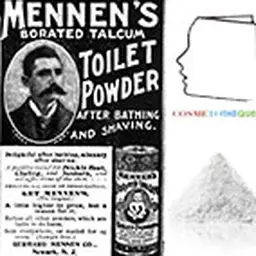

The technology of mineral oxide treatments began in the 1970s to facilitate their dispersion in water or in organic media, for industrial uses such as inks or paints. Several metal soap treatments were initially developed, aluminum stearate being the most commonly used.

But consumers have other expectations to improve the performance of make-up products, such as the feeling of well-being, skin affinity and durability…. After the initial developments based on metal soaps, several other techniques appeared and led to an impressive diversity of solutions.

Development and properties of surface treatment technologies

Cosmetic make-up consists mainly of pigments, fats and water in sometimes complex form systems. They generally consist of oily and/or aqueous phases. The correct dispersion of pigments in one or the other of these phases is essential. Initially, metal soap treatments were developed for cosmetic purposes. The hydrophobic properties of this treatment improved the stability of the make-up products to tears and water.

The good dispersion of pigments in fatty substances is a very important point, but not only. Other performance criteria are to be taken into consideration such as : - Dispersion in oils - Hydrophobicity - Skin Affinity - Pleasant feeling when applied - Good spreading on the skin - Low surface activity - Sebum control - Other Surface treatment techniques have been developed to meet these expectations.

The primary benefit of applying an organic compound to the surface of different minerals is that they will have comparable surface properties and therefore disperse homogeneously in the fatty or aqueous liquid phase.

Methods for preparing surface treatments

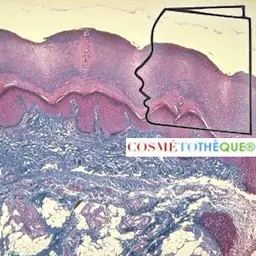

Generally, the surface of untreated metal oxides has many hydroxyl groups with which water molecules can easily combine. However, by using these surface hydroxyl groups, metal oxides can be modified by physico-chemical adsorption, hydrogen bonding or other reactions. When metallic oxides come into contact with a polymer solution, the polymer molecule will remain bound to the surface of the pigment as shown in the figure opposite.

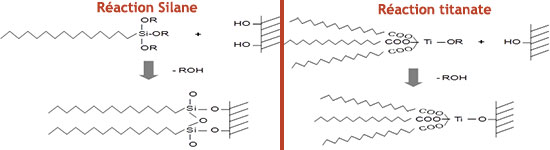

Organic compounds containing functional groups such as phosphate, amine, amide, carboxylic or hydroxyl may bind to the surface by chemical adsorption, hydrogen bonding or electrical charge. Alkyl alkoxy silanes and alkyl alkoxy titanates may react with surface hydroxyl groups of metal oxides according to the diagram below. The reaction with alkoxy occurs very easily in the presence of a small quantity of water and by heating. These are the most commonly used coating techniques.

Organic compounds containing carboxylic groups may also react with surface hydroxyl by esterification. However, this equilibrium reaction generates the production of water molecules that must be eliminated in the process. The industrial implementation of this type of reaction is difficult.

There are other techniques to perform surface treatments such as : - Polymerization on the surface of pigments - Mechano-fusion, a technology that consists in forcing small particles of the treatment material to integrate the metal oxide particles under the action of high shear forces delivered by specific equipment.

The diversity of surface treatments and their properties

Metal soaps have been at the origin of surface treatments for make-up products. Silicone oil treatments were then developed and widely used, as they give a soft and pleasant touch to the skin. The polysiloxane treatments were appreciated for their good compatibility with silicone oils, their strong hydrophobicity and an even softer feel.

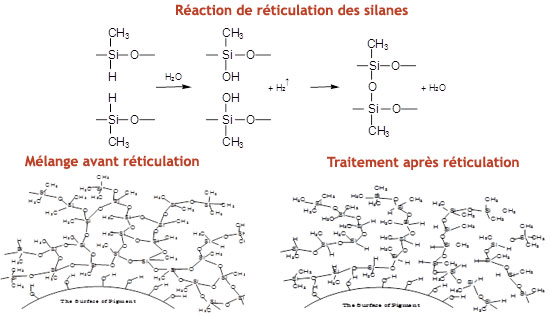

Two families of polysiloxanes were used in which m=0 or m=n (with m+n < 8). The polysiloxane molecules bind to the surface of the pigment through hydrogen bonds by simple mixing.

The following figures show the situation after the mixing phase. The silane molecule contains Si-H bonds. In the presence of water and by heating, the Si-H links react with each other and form a Si-O-Si network. Finally, at the end of the heating process, a"cage" structure encloses the pigment particles.

The search for the optimal dosage of treatment material

One of the questions is to determine the optimal percentage of treatment to obtain good hydrophobicity. The contact angle is a means of defining this quantity. This angle of contact with water is measured for different percentages of treatment. Above a certain percentage, there is no improvement in the contact angle. It is this percentage that is retained as optimal for the titanium dioxide quality considered. From this value and the specific surface of the pigment, it is possible to calculate the theoretical saturation value as shown by stars in the figure opposite. Two percent of this treatment is generally sufficient for standard titanium oxide grades.

The different surface treatments and their properties in terms of oil adsorption values

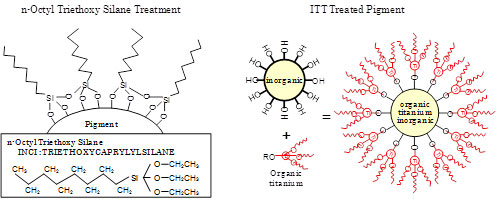

Different types of treatment make it possible to prepare treated pigments. They are identified as follows: - ASC for Acryl Silicone Copolymer - OTS for Octyl Triethoxy Silane - ITT for Isopropyl Triisostearoyl titanane or Alkyltitanate

Acrylic-silicone copolymer (ASC), alkyl alkoxy silane (octyl triethoxy silane (OTS)) and alkyl titanate (isopropyl triisostearoyl titanate (ITT)) are adsorbed to the surface of pigment particles. The last two molecules generate hydrocarbon chains on the surface of the particles. But the dispersion in the oils is different because there are three hydrocarbon chains per molecule in the ITT treatment and only one in the OTS treatment. In liquid cosmetic formulations, ITT treatment gives better dispersion quality and lower viscosity.

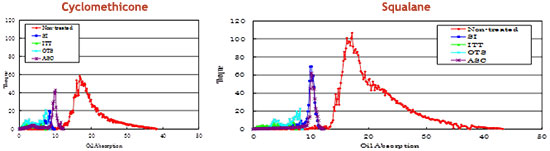

To evaluate the absorption properties of the different pigments treated, the equipment shown in the figure below is used. The different qualities of titanium oxide treated SI, ASC, OTS and ITT are introduced into the chamber of the apparatus. An oil is then introduced gradually at constant flow. The instrument measures the blade torque which increases with the viscosity of the dispersion until it reaches a maximum value and then decreases. The maximum torque value corresponds to the maximum oil adsorption.

Two types of oils were used: cyclomethicone (silicone oil) and squalane (isoparraffins). The torque graphs obtained for these two oils are as follows:

In the case of untreated titanium oxide, the torque increases with the addition of oil, which means that the adsorption rate is high and the dispersion becomes very thick. In comparison with the treated pigments, the maximum torque value is reached with a lower oil quantity. Then, when this maximum value is reached, the torque value decreases instantaneously. This means that the treated pigments have lower oil adsorption and provide less viscosity to the liquid formulations. This reduces the viscosity of the formulas, which is an important factor in formulation. .

A particularly remarkable treatment: fluorinated derivatives

The introduction of fluorinated compounds (perfluoro-alkyl phosphate) was an important step in the development of surface treatments. These molecules make it possible to obtain powders that are both hydrophobic and lipophobic. The good stability of make-up is not only affected by water, but also by sebum. And sebum leaves a shiny film on the face that women don't like. The use of pigments treated with perfluoro alkyl phosphates (PF) avoids this problem and makes it possible to formulate long-lasting foundations. The consequence is that the formulation of the products is made more difficult, because the pigments thus treated do not disperse in water or oils. Formulation devices had to be developed to overcome this difficulty.

The molecule used for this treatment contains traces of perfluorooctaneic acid (PFOA) that is not biodegradable and whose accumulation in nature could ultimately pose a risk to human health. There are no regulations limiting its use, but manufacturers of perfluorinated compounds have committed not to use PFOA by the end of 2015. A new PFOA-free treatment has been developed, based on perfluoroalkyl silane and sodium perfluoro ethyl-hexaphosphate.

Surface activity of pigment particles

Fukui et al. developed a method to evaluate the surface activity of pigment particles. This method allows acid/base values to be determined by the conversion ratio of isopropanol to propylene or acetone. The application of this technique demonstrates that surface treatments are very important for the protection of active sites on the surface of pigment particles. This is even more marked in the case of very fine particles to such an extent that, nowadays, only the treated nano qualities of zinc oxide and titanium dioxide can be used in sunscreen formulations.

Hybrid surface treatments

Surface treatments generate essential properties for the formulation of cosmetic products. However, for example, the lipophobia of the perfluoro alkyl phosphate treatment makes it difficult to disperse, but provides a powdery feel and good skin adhesion. On the contrary, the amino acid treatment will provide a good affinity on the skin but a bad spreading and a not very pleasant touch. Hybrid treatments have therefore been developed in order to take advantage of the interesting properties of several treatments, while reducing the impact of their negative sides.

An example of this hybrid treatment technology is a combination of perfluoroalkyl phosphate and octyl triethoxy silane. This association gives a superior hydrophobia, but also a pleasant touch and a better dispersion in the fatty substances.

Another example is the combination of amino acid and isopropyl triisostearyl titanate which provides a good skin affinity, a soft and creamy touch and a very good spread.

The different treatment processes

There are two main manufacturing methods. - One is called a"dry process" in which the processing agents are simply added to the pigment in a blender. - The other, the"wet process", consists of"dissolving the treatment agents in a solvent, which may be water, and then introducing this solution into a tank containing the pigment previously dispersed in a liquid phase. The solvent or water is then removed. The treated pigment is then dried and finely ground.

The dry forms of pigment particles are in the form of agglomerates. Under'dry process' conditions, the treatment material will be applied to the surface of these agglomerates. After grinding, the untreated internal parts of these agglomerates will emerge and this will result in poor homogeneity of the treatment.

In the wet process, the entire system is in the liquid phase. The molecules of the treatment material penetrate the agglomerates more easily and can attach themselves to almost the entire surface of the particles.

Wet processing" is more homogeneous and provides better stability to cosmetic formulations.

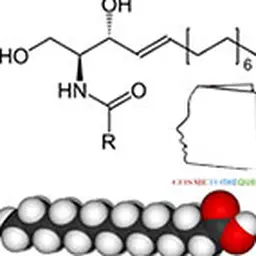

The latest developments: the natural trend

Nowadays,"natural" is at the centre of consumer demand. Surfactants are a problem. To meet this demand, a new ASL treatment has been developed. It is carried out by means of a substance comprising an alkyl group and a chain of amino acids made up of three glucose-lysine-glucose molecules. This substance does not contain surfactants but behaves as an excellent dispersing agent and allows a fine, uniform and stable emulsion to be obtained from a mixture of oil and water (40/60). This treatment opens the way to new concepts for aqueous formulations.

Water dispersible treatments

Mineral oxides are hydrophilic but have variable isoelectric values, which means that the different oxides do not disperse uniformly in the formulations. A microcrystalline cellulose treatment has been developed to solve this problem. This cellulose based treatment has the property of adsorbing water and provides a very pleasant touch on the skin. Nevertheless, the actual high density of this treatment is likely to create problems in low viscosity formulations.

A nonionic hydrophilic hybrid compound based on polyethylene glycol silane and tetraethoxy silane was also presented, but its compatibility in aqueous media was not as good as desired.

Finally, the research focused on anionic and cationic polymers. The use of cationic polymers makes it possible to bring a positive charge to the surface of the pigment whatever the pH value. This means that pigments treated in this way will disperse easily in water.

By treating with an anionic polymer, a variable response can be induced depending on the pH. Between pH 3 and 8, the treated pigment is hydrophobic, but beyond pH 9, it becomes hydrophilic. This property makes it possible to formulate hydrophobic cosmetics when applied to the skin, but which are easily removed with water by applying a cleansing product containing soaps or other alkaline compounds.

Conclusion

This table summarises the different types of treatment currently offered by one of the main operators in this specialty market.

|

Properties of the different types of treatment |

||

|

Desired properties |

Functionality of the processing |

Type of treatment |

|

Long lasting |

Hydrophobicity |

Perfluoroalkyl phosphate Polysiloxane Alkyl silane Alkyl titanate Metal soap |

|

Lipophobia |

Perfluoroalkyl phosphate |

|

|

Adhesiveness |

Adhesiveness |

Lauroyl lysine Amino acid Metal soap |

|

Dispersion |

Low friction coefficient Creamy touch |

Lauroyl lysine Metal soap Alkyl silane Alkyl titanate |

|

Fluidability |

Polysiloxane |

|

|

Hydration |

Capturing moisture |

Cellulose Bio-surfactant |

After 30 years of development, many types of treatments have been proposed to formulators to modify the properties of metal oxides and provide them with new functionalities. Nowadays, it is inconceivable to develop modern formulas without using treated pigments.

A thousand years ago, the Japanese writer Sei-Shonagon complained about the poor stability of her make-up. This criticism is now irrelevant. Progress will be made in the use of natural, renewable and non-toxic substances to continue to offer pigments with a range of new properties and to make cosmetic products even more effective.

| Contribution made by Takumi Tanaka Takumi Tanaka is Director of R&D at Daïto Kasei Kogyo Co., Ltd. Graduated from Kyoto University in polymer science, he joined the Daïto Kasei group in 1992 after having held research positions at Duke University in the USA, then as a consultant at AT&T. Serge Grizzo, Past President of the French Society of Cosmetology and recognized expert in pigments and coloring fillers, translated his text. The original article will be published on the Cosmetotheque website . |

| About Daïto Kose Kogyo Ltd Daito Kasei Kogyo was founded in 1950 in Japan and has its headquarters in Osaka. The company now has four plants in Japan, in Osaka, Fukui, Okayama and Niigata, and has just inaugurated in 2015 its first production unit outside Japan in Frépillon in the Val d'Oise in France. The Company employs nearly 200 people and 80% of its activity is devoted to raw materials for the cosmetics industry. The development of innovative technologies for the treatment of powders has given it a leading position in this segment and today enables it to serve the largest Japanese and international cosmetic companies. Daito Kasei Kogyo uses two commercial distribution subsidiaries in France and China and a network of local distributors covering some sixty countries. The recent establishment of a production unit in France testifies to the company's good health and its desire to get closer to its main Western customers. |